PUMP INSTALLATION AND

APPLICATIONS

These pumps are

recommended for clean water and fluids which are not

chemically aggressive to the pump components. They are

principally used for civil, industrial and agricultural

applications, where they make the most of their sturdiness and

dependability.They are manufactured to EN 733-DIN 24255

standards.Overall dimensions,sizes and positions of suction

and delivery openings,support feet and other dimensional

characteristics comply with these standards.This means that

users can be sure these pumps will meet even the most

demanding heavy-duty needs and that they can be perfectly

interchanged with other standardized pumps.Their structural

shape allows dismantling without disconnecting the pump body

from the pipeline (back pull-out),making them easy to use in

widely varying conditions.

They should be installed in a

covered area, protected against the weather.

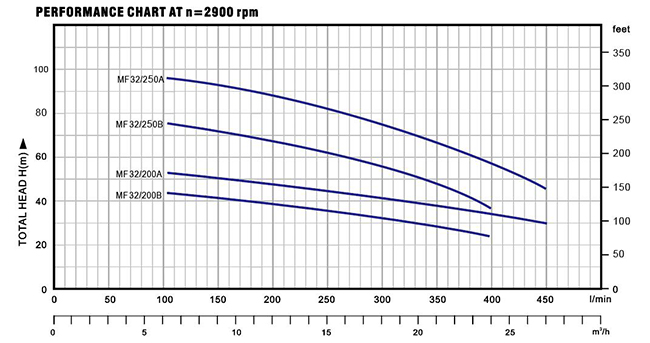

PERFORMANCE

MFM pumps come in a wide

and well-diversified range. Characteristic curves for the

different models are distributed in a rational manner,making

it easy to select the model most suited to each specific user

requirement.This together with high performance efficiency,

means big savings in operating costs since these are powerful

machines often intended for continuous duty.

This series of

pumps is characteried by:

¡ù highly stable and broad

characteristic curves;

¡ù performance characterized by high

absolute values over the majority of the curve;

¡ù flat

absorption curves at high delivery rates,preventing motor

overloading even during prolonged use;

¡ù good suction

capacities at both low and high delivery rates.

STRUCTURAL CHARACTERISTICS

¡ù cast iron

pump body , built with flanged suction and delivery

openings.

¡ù cast iron pump body cover which closes the rear

pump body and houses the mechanical seal.

¡ù brass impeller

with centrifugal radial flow type.

¡ù stainless steel

shaft

¡ù stainless steel mechanical seal(graphite to

SiC)

¡ù protection IP 44.

¡ù with thermal overload

protector in single phase motor up to 1.5 KW.

The remaining

single phase motors and all three phase motors require an

adequate external motor protector,and connections are to

be according to current standards.

¡ù NSK bearing or

local bearing

WARRANTY:1 YEAR(according to our general sales

conditions)

FLOW RATE Q

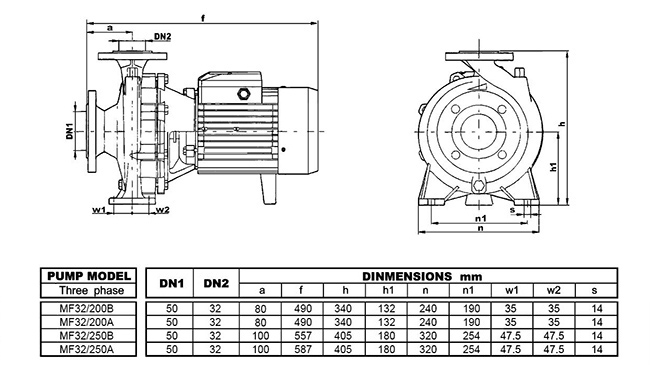

PUMP MODEL |

POWER |

Q

m3/h |

0 |

6 |

9 |

12 |

15 |

18 |

21 |

24 |

27 |

Three phase |

KW |

HP |

l/min |

0 |

100 |

150 |

200 |

250 |

300 |

350 |

400 |

450 |

MF32/200B |

3 |

4 |

H

M |

44 |

43 |

41 |

39 |

35.5 |

32 |

28 |

24 |

|

MF32/200A |

4 |

5.5 |

54 |

52 |

50 |

48 |

45 |

42 |

38 |

34 |

|

MF32/250B |

5.5 |

7.5 |

79 |

75 |

71 |

67 |

62 |

56 |

48 |

37 |

|

MF32/250A |

7.5 |

10 |

99 |

95.5 |

92 |

88 |

83 |

76 |

68 |

58 |

46 |

H=TOTAL

HEAD IN METERS. Q=FLOW RATE

|